|

E46 330 Rear Brake Conversion DIY |

|

After completing the front brake conversion it was time for the rear ones. Good upgrade but no as simple or straightforward as the front one.

Researching, I came to the conclusion that

the only limitation for a direct bolt on upgrade, is the inner diameter of the

330 rotor, which is larger, requiring the e-brake assembly from a 330 to be

transplanted to the lower model cars in order to work properly.

320 With cutout line

330 Compared:

Getting dimensions:

Rear calipers, rusted, ready for their transformation

After 2 days in rust inhibitor and more cleaning:

Painted with heat resistant paint to prevent rusting:

OEM 330 Rear Disks

Side to side

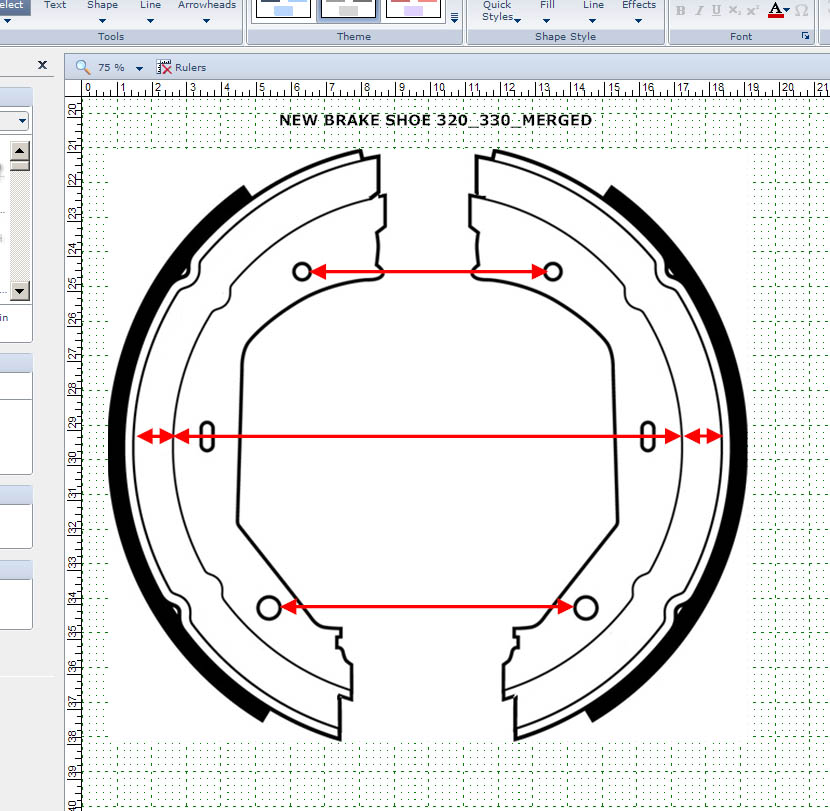

Fabricating some holders to preserve diameter and positioning of shoes so that I don't have to carry the disk with me all the time

Increase of diameter by 11.8mm

Time to cut the shoes to fabricate the franken-shoe :)

Removing the braking plate out of the 320 shoe

How it will look

Marking the area to be cut on the 330 shoe

Professional grinder makes cutting easier

Spot welding the adapters/extensions to test fit!

I believe we are very accurate!

Both sides finished!

Car on jack and jack stands! - Handbrake DIY

Removing 2x16mm bolts to release caliper

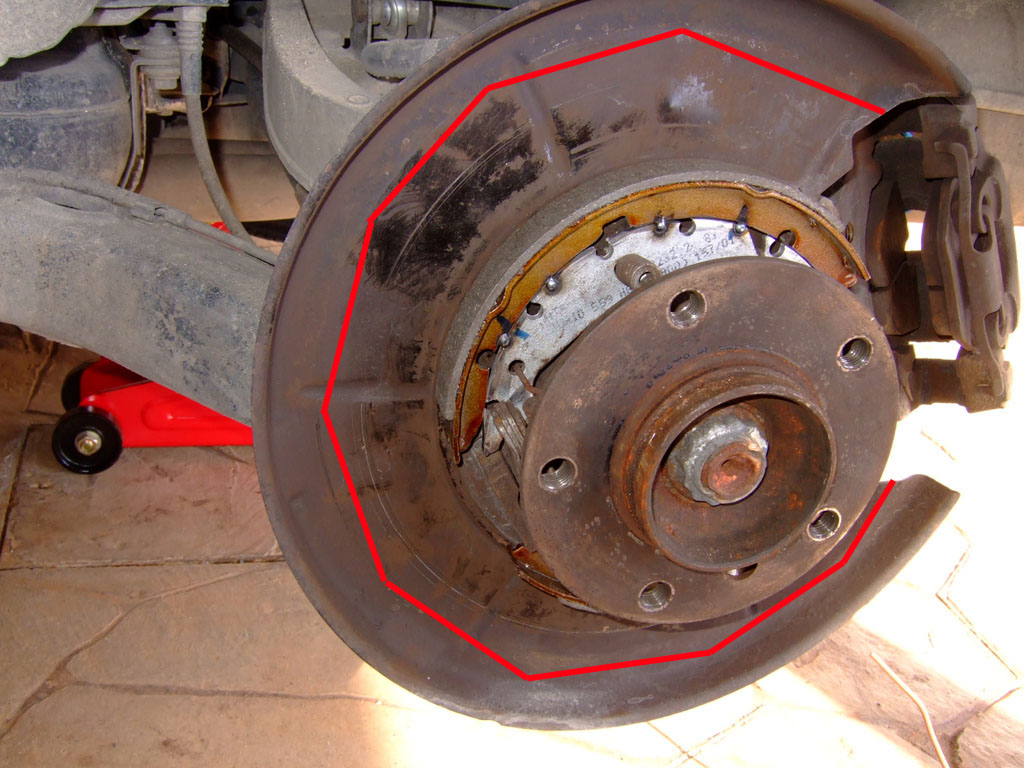

After removing the rotor, the handbrake assembly appears. First we remove the spring using needle nose pliers and safety glasses since everything is spring loaded and may fly anywhere! Then that little conical adjuster is removed.

The other side of the handbrake has another spring to be removed as well, same way.

To remove the shoes, insert a 6mm hex key through the wheel bolt hole, twist 90 degrees and remove the retaining pin

Reassembly using the new hybrid brake shoes to test fit!

The dust shield took a beating since it was in the way of the larger 330 rotors, I had to bend it out of the way, that is until it's time to do the rear bearings, where I will get a proper 330 based dust shield as well. Unfortunately, without taking the hub apart it's impossible to remove it.

After verifying correct fitting, I removed the shoes again, fully welded them, painted them with rust prevention paint, and re-assembled them back! Here's the end result!

I didn't get into detail regarding the rear caliper installation, since it's bolt on, using the same mounts and brake lines. Brake pad sensor is the same as well!

DIY Continued with installation of PBR (Axxis) ULT Ceramic pads. Previously I run some used ferodo pads that came with the calipers I bought because I didn't want to spend money in case the mod with the handbrake did not succeed. Additionally, I installed some modded 330 dust plates as well. I had to cut them and weld them on the existing ones due to the fact that the 330 dust plates need 330 trainling arms etc to fit. So again, cutting and welding was the only option.

Ceramic pads, now matched with the front ones!

330 Rear Dust plates

I marked and cut the existing 320 dust plates as per markings above and then did the same on the 330 plates. Afterwards I spot welded them in place to make a hybrid expanded 320 dust plate that would accommodate the 330 rotors.

End result with new pads and plates installed.

Wheels could use a bit of a cleaning I know. |